— Seeking fundamental rules for the control of microstructures and properties in metallic materials —

Our group is pursuing the studies on the microstructure and property control of metals and alloys (such as steels and titanium alloys) which are indispensable for the development of modern society, through phase transformation, precipitation and deformation /recrystallization.

|

|

||||||||||||||||||

Fundamental study on phase transformation and precipitation

Microstructure represents various kinds of heterogeneities in the metallic materials, i.e., grains, component phases, lattice defects and chemical inhomogeneity such as impurity/alloying elements. Microstructure can be modified through the control of phase transformation/precipitation and deformation/recrystallization by adjusting the composition of materials and through the processing routes (heat treatment, deformation). Such expertise in microstructure control is very important in the current materials production from the viewpoints of energy saving and recycling.

We study the microstructure of metallic materials by microscopy in a wide range of scales. Fundamentals of microstructure formation (thermodynamics, kinetics, crystallography) are examined both theoretically and experimentally to clarify the key factors for microstructure control.

|

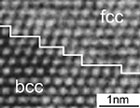

Figure 1 Atomic structure of the austenite/martensite interphase boundary (high-resolution electron micrograph). Regularly spaced mono-atomic steps are transformation dislocations whose migration accompanies the stacking sequence change. |

Texture formation and related property change in metallic materials

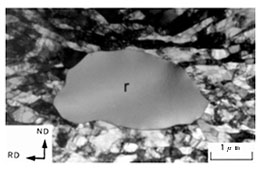

Texture of materials (preference of special grain orientations) affects to properties of materials such as ultra-low carbon sheet steels and Fe-Si electric steels. Texture can be formed during deformation, recrystallization and even in phase transformations. We aims to clarify the mechanisms of texture formation for more sophisticated texture and property control of materials.

|

Figure 2 A recrystallized grain (denoted as "r")in Fe-15%Cr ferritic stainless steel (transmission electron micrograph). |

Strengthening of steels and titanium alloys

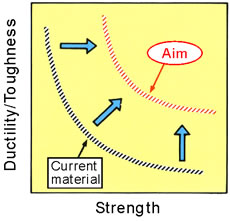

Steel is the largest in the production among metallic materials and the most important structural material without doubt. Titanium and its alloys exhibit superior strength/weight ratio with good corrosion resistance and are expected to be more important as structural materials. We aims strengthening and toughening of steels and titanium alloys by thermomechanical processing to control phase transformation, precipitation and recrystallization.

|

|

Figure

3 Strength-toughness balance of metallic materials. As strength (es.g., yield stress against plastic deformation) increases, toughness (fracture strength) decreases in general. |

|

Development of ferrous shape memory alloys

Shape memory alloys are widely used in our modern life. TiNi alloys, most widely used, are expensive so that the needs for low-cost ferrous shape memory alloys are increasing.

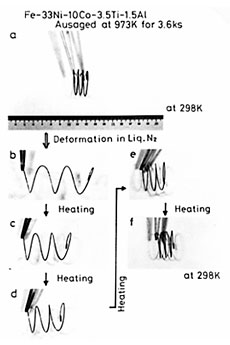

We study the martensitic transformation (diffusionless / displacive transformation) which plays major roles in shape memory effects and developing new ferrous shape memory alloys of high-performance, such as Fe-Ni-Co-Ti-(Al) and Fe-Mn-Si-C.

|

Figure 4 Shape recovery of Fe-Ni-Co-Ti-Al developed in our group. An alloy coil deformed at liquid nitrogen temperature recovers its original shape by heating to room temperature. Precipitation of nano-size coherent intermetallic compounds plays an important role on this behavior. |

Development of high-strain rate superplastic materials

Metallic materials with suitable microstructures sometimes exhibit very low flow stress and large elongation when they are deformed in the range of specific deformation temperature and strain rate, they sometimes exhibits . This phenomena called “superplasticity” is quite attractive in the aspects of processing of materials hard to be deformed and near-net shape deformation.

We are mainly focusing on the property control of two-phase materials

such as duplex stainless steels, ultra-high carbon steels and (![]() +

+![]() )

titanium alloys by various thermomechanical processing and improvement

of superplastic performance at higher strain rates.

)

titanium alloys by various thermomechanical processing and improvement

of superplastic performance at higher strain rates.

|

| Figure 5 |